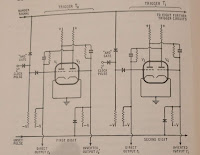

Document breadboard builds by writing Python code

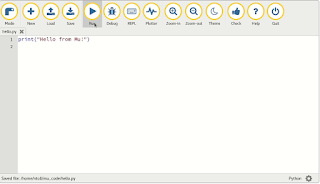

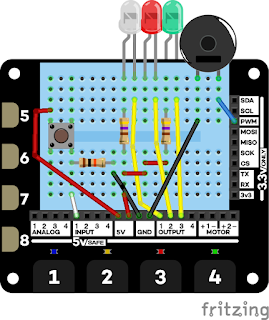

In my last post I mentioned that I was using breadboarder - a Python program that eases the pain of documenting breadboard-based projects. You write a descriptiopn of your project using a Python-based DSL - a domain-specific language. It lets you explain what wire or component to add to the breadboard, and where to connect it. You write code like this: And it generates markdown and png files which render like this: It saves hours of layout, you can build complex projects out of simple ones, and everything is under source control. I need to improve the documentation but breadboarder is on GitHub .