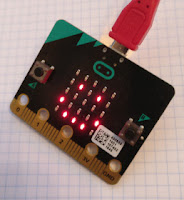

MonkMakes boards for the micro:bit

MonkMakes is the Hardware business started by Simon and Linda Monk to complement Simon's many excellent maker books. They've just released three new boards for the micro:bit. Today I had a play with their sensor board , which has a light sensor, a microphone and a thermometer. It's incredibly easy to connect to the micro:bit. I'm clumsy, but I wired it up in a minute at most. There's sample Python code a little way down on the MonkMakes website page , but WordPress has mangled it a bit; the code wouldn't run until I replaced all the em-dashes with minus signs and replaced all the double quotes. There are also a lot of redundant blank lines, but that's just a cosmetic issue. Once you've fixed those issues you can use Mu 's REPL to display the light level, temperature and sound level at pone second intervals. The microphone seems to be directional. I had loud music on when testing, which didn't register, but it responded well to a clap or...