Making Shrimp (Arduino) projects permanent with Stripboard

Making the Shrimp is a great way to get started with Arduino technology. The Shrimp is a low-cost Arduino clone on a breadboard. Once you've prototyped a Shrimp-based project you'll probably want to make a more permanent version, and stripboard is a great way to do that.

The Shrimping It! website offers a low-cost stripboard kit and has a few pictures to get you started, but I suspect some beginners would like some more detail.

I'm about to make a simple prototype for a new project I'm working on and I thought it would be worth while documenting the process. This is not a soldering guide: if you need one, the Shrimping site recommends this.

The stripboard kit contains three items: a generously sized stripboard, a strip of headers, and a DIL socket. You'll need the contents of a standard Shrimp kit as well.

You'll also need some tools.

I used

Then I polished the underside of the board to make it easier to solder.

The next step was to decide where to place the DIL socket which would contain the Atmel AVR microprocessor chip. That's the heart of the Arduino/Shrimp.

In order to insert the DIL socket into the board I found I had to straighten and align its pins. I used a special-purpose tool but if you're careful you can just use a level surface like a table top and align the pins by hand.

I placed mine so that there were three blank rows to the left of the chip, and two to the right. I left two empty rows above and five below.

That way there was room for all the components and the predrilled mounting holes on the stripboard did not overlap any of the microprocessor's pins.

I inserted the remaining components using the diagram from the Shrimping website to check that everything was going to fit, and then removed them so that I could start soldering.

I used some drafting tape to keep the IC socket properly seated on the board and soldered the top left and bottom right pins. Then I checked the socket was properly seated on the board and soldered the remaining pins.

I inserted the remaining components one by one, soldering them in and trimming the leads as I went. I decided not to use all the components in the kit; in particular, I didn't add the LED on pin 13, or its associated resistor, as they are not required for the application I have in mind.

This makes for a neater layout, but it's very fiddly. I don't recommend it unless you are an experienced constructor.

If you purchase the book you'll get that and all other updates for free, and you'll be protected by Leanpub's unconditional 45 day guarantee.

That section will complete the e-book, and the price will be going up on Monday morning to reflect that. If you want to get a copy at the current price, get it today!

The Shrimping It! website offers a low-cost stripboard kit and has a few pictures to get you started, but I suspect some beginners would like some more detail.

I'm about to make a simple prototype for a new project I'm working on and I thought it would be worth while documenting the process. This is not a soldering guide: if you need one, the Shrimping site recommends this.

|

| Kit contents |

You'll also need some tools.

I used

- a soldering iron

- a small fume filter

- a pair of wire cutters

- a polisher to clean the copper

- a nibbler (used to cut the board, but a hacksaw would do just as well)

- a spot face cutter (a special tool to make breaks in stripboard tracks, well worth the cost if you are doing a lot of stripboard construction)

- a test meter to find any mistakes (there were some)

- a de-soldering pump just in case you make mistakes. I needed it :)

- a pin straightener

Preparing the board

The first thing I did was to cut the stripboard to size. There's enough board to build three Shrimps if you're careful. You'll use the full width of the board but you only need 11 rows.Then I polished the underside of the board to make it easier to solder.

|

| pin straightener |

In order to insert the DIL socket into the board I found I had to straighten and align its pins. I used a special-purpose tool but if you're careful you can just use a level surface like a table top and align the pins by hand.

Locating the IC socket

|

| Socket location |

That way there was room for all the components and the predrilled mounting holes on the stripboard did not overlap any of the microprocessor's pins.

I inserted the remaining components using the diagram from the Shrimping website to check that everything was going to fit, and then removed them so that I could start soldering.

I used some drafting tape to keep the IC socket properly seated on the board and soldered the top left and bottom right pins. Then I checked the socket was properly seated on the board and soldered the remaining pins.

Adding the rest of the components

|

| Completed board |

A minor change to the wiring

I made one other change to the layout on the Shrimping website; I moved the red and green power wires under the board. |

| Board underside |

Checking the soldering

I always do a couple of checks before I apply power to a newly-soldered board.

A visual check often show poor joints or solder bridges (unwanted connections between tracks). It won't catch everything, though, so I also do a quick test using a meter.

I look for short circuits between adjacent tracks on the stripboard.

Most solder bridges on stripboard connect one track to the one next to it; I use a meter that gives an audible warning when the two test leads are connected.

It takes a minute at most to check for short between the tracks, and the test seems to catch the vast majority of soldering problems.

In this case I found a solder bridge and used the iron and the de-soldering pump to remove the excess solder. I retested the board and this time the conductivity test passed.

Time to fire up the board!

|

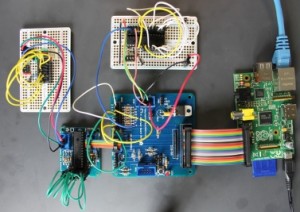

| Shrimp and CP2102 programmer |

I connected the CP2102 programmer to the appropriate pins and plugged it into the USB port. Then I started up the Arduino environment, and checked that /dev/ttyUSB0 was showing up in the list of ports. I opened my Morse flasher sketch and uploaded it.

The IDE displayed the reassuring 'Done Uploading' message. If you see that you can be pretty sure that everything is working OK.

I went on to test the Morse application which worked as it should. There was no LED to flash but the application printed out the morse representation of its input.

The pins along the edge of the board should make it easy to connect the rest of the prototype I'm building. The Shrimp parts and board kit cost £5.30, and postage adds £1. That's a very economical way to build a permanent version of your project.

Make the Shrimp - buy the book

Tomorrow I'm going to add information about the stripboard version to 'Making the Shrimp'.If you purchase the book you'll get that and all other updates for free, and you'll be protected by Leanpub's unconditional 45 day guarantee.

That section will complete the e-book, and the price will be going up on Monday morning to reflect that. If you want to get a copy at the current price, get it today!

You should pick up a soldering iron with at least 30 watts of power. Soldering irons with low wattage take longer to heat up and are not consistent holding the temperature. Details here: https://solderingironguide.com/reviews/wall-lenk-soldering-irons

ReplyDelete