Make your own strip-board breakout boards

A useful trick for Makers

In this article you'll see when you should build your own breakout boards, and you'll learn a useful trick to use when making them.

Breakout boards rock

Digital Makers can often make projects faster by using breakout boards.

A breakout board is a small but useful module that you can use to compose your project. There are hundreds of breakout boards available. Many are based on tiny SMD chips that are tricky to solder. You can save time and reduce the risk of mistakes by buying a ready-made breakout board.

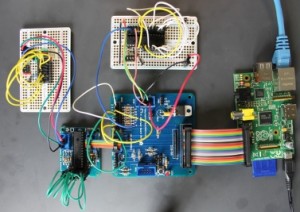

Here's an Adafruit breakout board I used in the Raspberry Pi version of Lazydoro.

Of course, you can only buy a ready-made board if you can find one that does what you need,

If there isn't, consider making one!

Why bother with self-built breakouts?

Why not just put everything you need on the main project board?

There are advantages to a design that uses pluggable modules. You can usually test the module on its own, and there's a good chance that you can re-use the model (or at least the design) in future projects.

Hardware and software developers have been doing this for decades. Well-designed hardware and software modules reduce coupling, increase cohesion, and increase quality.

Here's a concrete example from a current project.

A buzzer module.

One of my projects (lazydoro) needed a buzzer.

The project is based on the Raspberry Pi Pico W, so digital outputs are limited to 3.3 volts. Some active buzzers will work at that voltage, but they sound a bit feeble. I needed to hear the buzzer in the next room, so I wanted to drive it at 5 volts.

I decided to build a module.

The module design

The circuit is simple. It uses an inexpensive BC337 NPN transistor as a switch. A 3.3 volt control signal applied to the base of the transistor runs the switch on, reducing the output voltage to just over 0 volts. That results in a 5 volt potential difference across the buzzer, which then buzzes loudly.

Here's the schematic.

NB: In the schematic, power, ground and the signal come in on the right!

Mark 1 - oh, dear

I built the module on a small piece of strip-board. Since you can only solder strip-board on the copper side of the board, I soldered a 3-way female header on the module and a 3-way male header on the main board.

It worked, but it didn't look very pretty in place.

Mark 2 - the trick

Luckily I remembered an old trick which resulted in a much neater version.

If you solder header pins without modding them the pins are too short to plug into a female header.

Luckily, you can push the plastic to the top of the pins so they look like this:

Now you can solder them to strip-board and the pins are long enough to work.

Here's the new module:

and here's the strip-board design. As you can see, the design fits on a standard 9-strip board, and you don't need to cut any of the strips.

I added a female header to the main board and inserted the new module. Here it is in place. It works perfectly and looks much better now the buzzer is on top!

Summary

Breakout boards are a great times-saver. If you can't find one that does what you want, it's often easy (and satisfying) to make your own.

If you're using strip-board you can easily adapt male headers to that you can solder them to the copper side of the strip-board.

Comments

Post a Comment